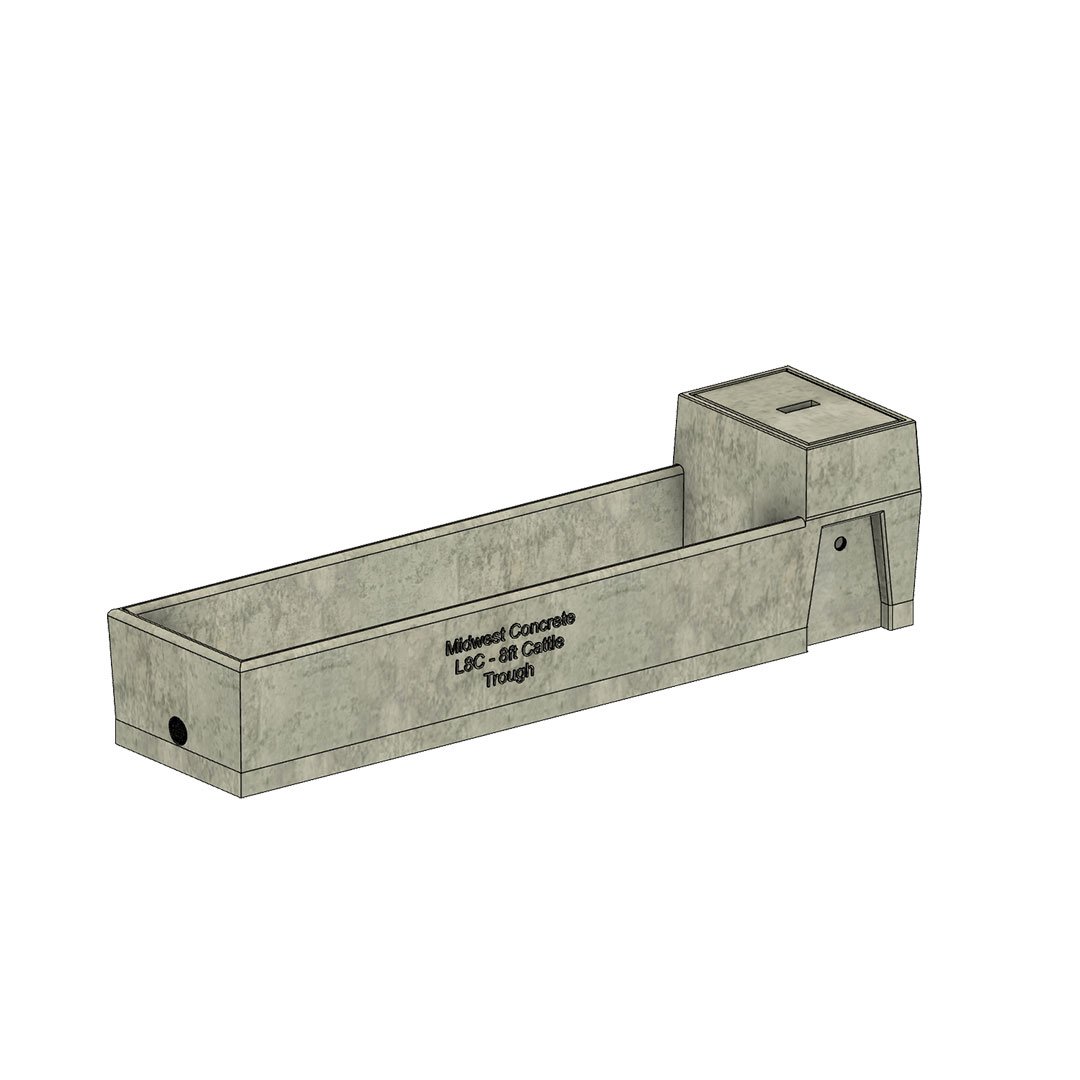

Precast Concrete Water Troughs

Mid West Concrete has been manufacturing stock water troughs since 1985 and has grown to service clients all over New South Wales and Victoria.

Our troughs are recognised for leading the industry in terms of design innovations that make them strong, durable, cattle ‘damage’-resistant, simple to set up and simple to clean.

The trough range is standard with brass cast-in inlet and drain fittings. We find these give the best durability and hassle-free performance.

Our valves are a cast stainless steel manufactured just for us to our high standards of durability, serviceability and performance. We are happy to recommend the best valve for your application - simply give us a call to discuss.

Mid West Concrete troughs are made using Australian standard mesh and bar reinforcing. In some instances, we will use corrosion resistant fibre additives to achieve a desired strength specification.

As standard, our concrete products are made with 40MPa concrete in our own design moulds. We use environmentally friendly release agents and have regular testing conducted on our concrete to ensure we exceed our target strengths.

KEY FEATURES

40MPa concrete

40MPa concrete is the standard for industrial concrete manufacture. Don’t accept anything less and ensure you ask for the test certificates.

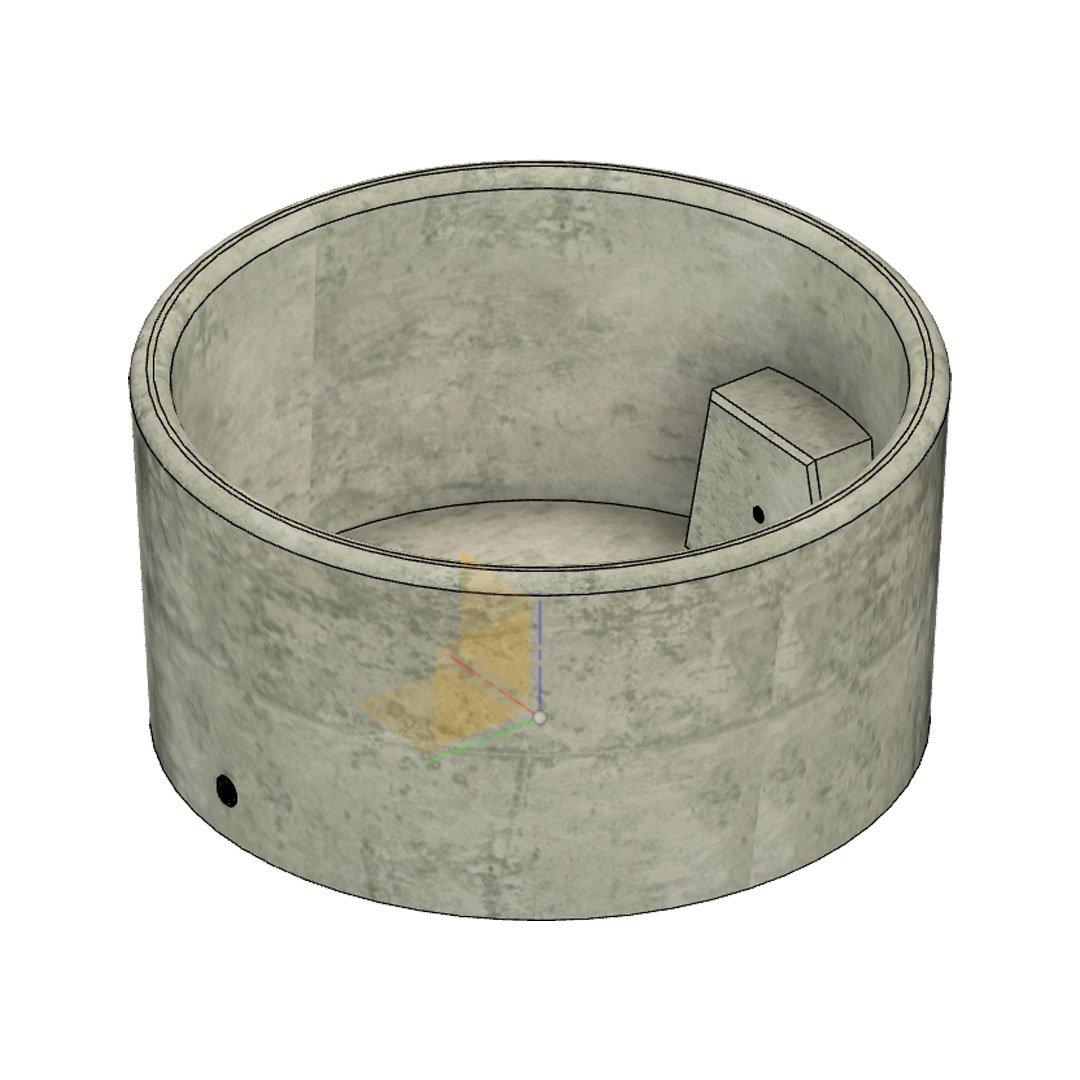

Stock-proof float cover

Our float box lids are cast concrete and fibre reinforced, ensuring your stock don’t dislodge covers and damage valves.

Heavy-duty design

Our troughs are heavy-duty and designed to withstand stock yards, paddocks and feedlots.

Deep

Depth of your trough is important. Go the deepest you can for your stock and layout. Deeper water stays cooler in hot weather and is less likely to freeze in cold weather.

AS steel reinforced

Steel reinforced with AS/NZS 4671 Steel. Mesh, bar and custom-made ligatures are incorporated into our products.

Brass fittings

Our bung housing and valve collar are cast in brass parts. Because of this we get great corrosion resistance and adherence to the concrete during casting.

Free-standing - heavy

Our troughs are generally around a tonne each for an 8-footer which means they withstand cattle pushing and leaning on them.

Float box inbuilt into trough body

Our float boxes are built into the rectangle troughs to stop them from being dislodged or tipped off. If you don’t like this, go with a round trough and choose the optional float cover. Still heavy-duty, but the option is yours.

“Mid West Concrete were fantastic in all aspects of the transaction from strat to finish. Delivery was also made simple and and professional by the delivery driver”